Electrical Contact Plates:

what they are and how they are produced

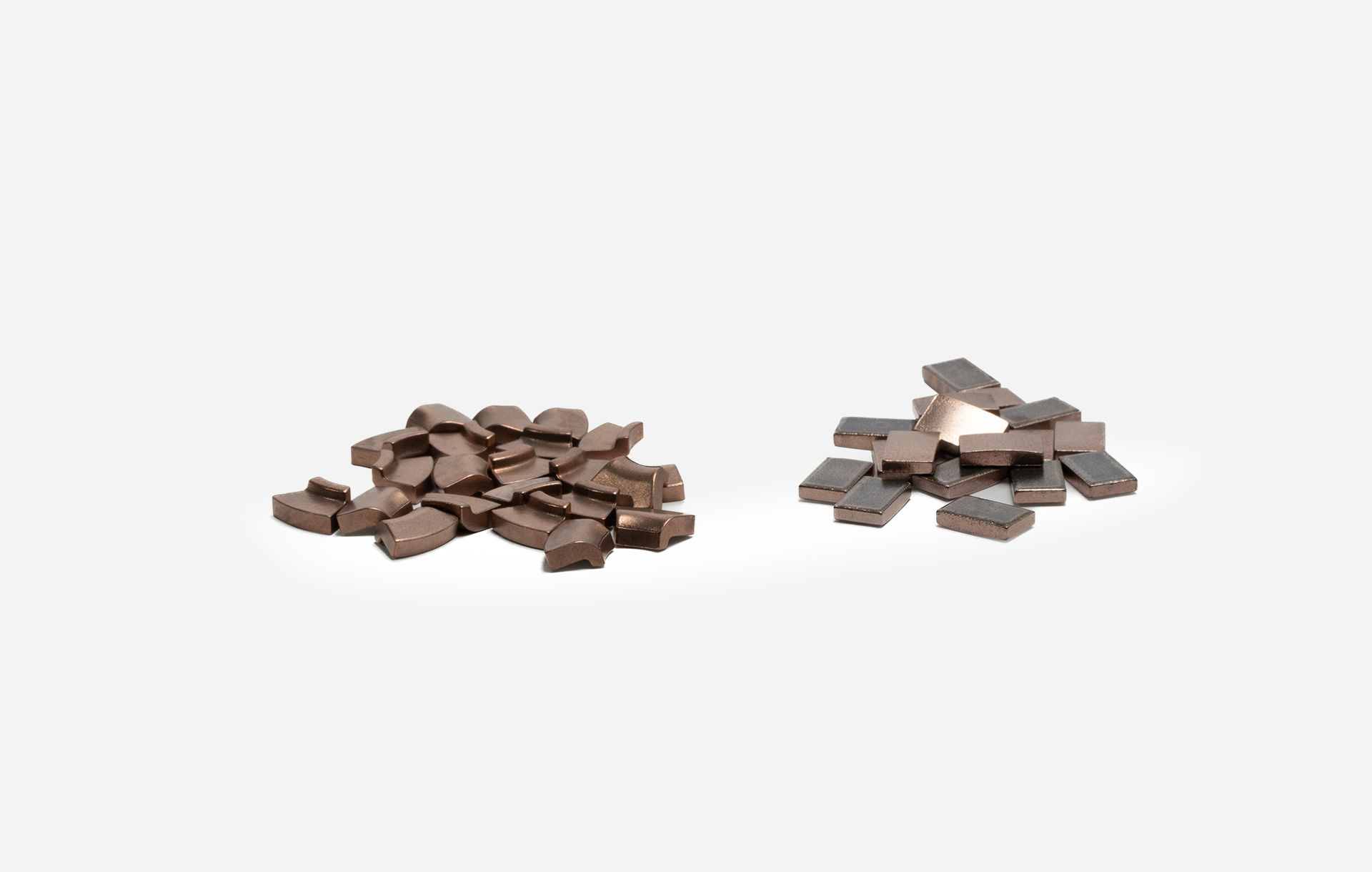

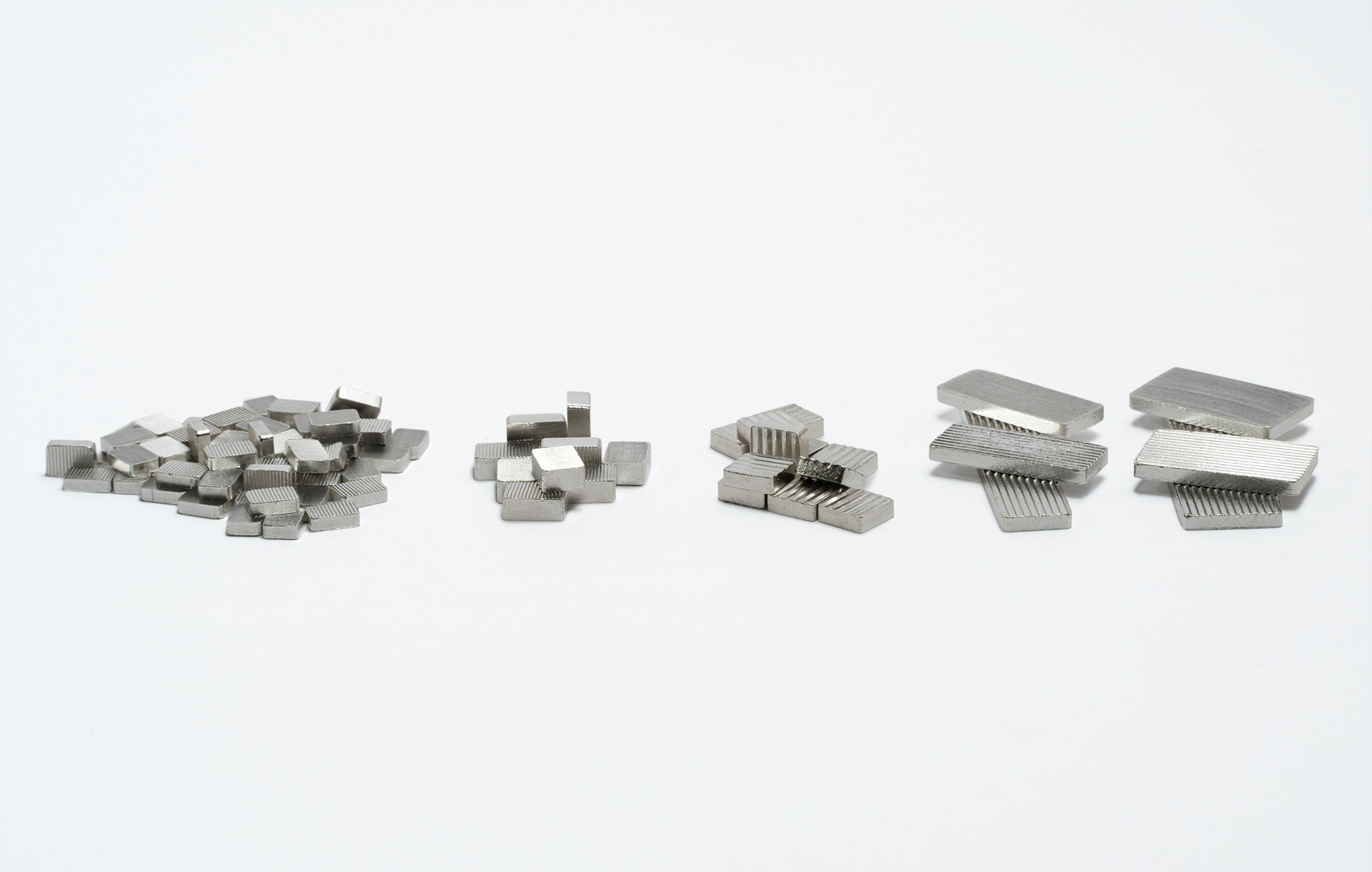

The sintered plates of our production are parallelepipeds of different sizes, produced by a multistage process that mainly involves mixing the powders, pressing, sintering, extrusion, cutting and coining.

In the case of silver graphite sintered plates (AgC sintered plates), the conceived process allows to obtain the alignment of the graphite fibers along the desired direction and a layer of brazing pure silver. The graphite fibers, arranged perpendicular to the contact surface, significantly reduce the risk of sticking to the electrical contacts.

In the case of silver graphite sintered plates (AgC sintered plates), the conceived process allows to obtain the alignment of the graphite fibers along the desired direction and a layer of brazing pure silver. The graphite fibers, arranged perpendicular to the contact surface, significantly reduce the risk of sticking to the electrical contacts.

Why should you rely on us for the production of plates?

We have many years of experience in the field of sintered plates and we produce millions of pieces per year. The continuous study of technological solutions, the state-of-the-art laboratory and an important technical know-how allow us to master a series of production processes that guarantee high reliability. We are able to guarantee the requests for each of your plates!

Our materials:

- Silver Nickel Sintered Plates (AgNI)

- Silver Graphite Sintered Plates (AgC)

- Tungsten Copper Sintered Plates (WCu)

- Tungsten Silver Sintered Plates (WAg)

Our “added value”

- Flexibility: We adapt our production to your needs to achieve the best result.

- Customization: Rounded edges upon request and notching on one side and / or deposition of brazing alloy

- Quality: Test of characteristics and certificate for each batch. Chemical-physical characteristics and metallographic structure according to the requests

- Product care: Careful packaging, taking all necessary precautions to ensure good preservation

Main

Characteristics

- Product dimensions: Parallelepipeds of different sizes with volumes from 0.05 to 20 cm3. Rounded edges upon request.

Possibility of notching on one side and / or deposition of brazing alloy. - Chemical-physical characteristics: Chemical-physical characteristics and homogeneous metallographic structure, which can be customized according to request. Excellent electrical and thermal conductivity, even for long periods of work.

- Packaging: Accurate, according to your prescriptions.

- Certification: We certify each batch.

- Surface: Clean and Deoxidized.

Surface roughness according to your specifications. - Order quantity: Possibility of mass production of large batches.