Wires for electrical contacts:

how are they produced?

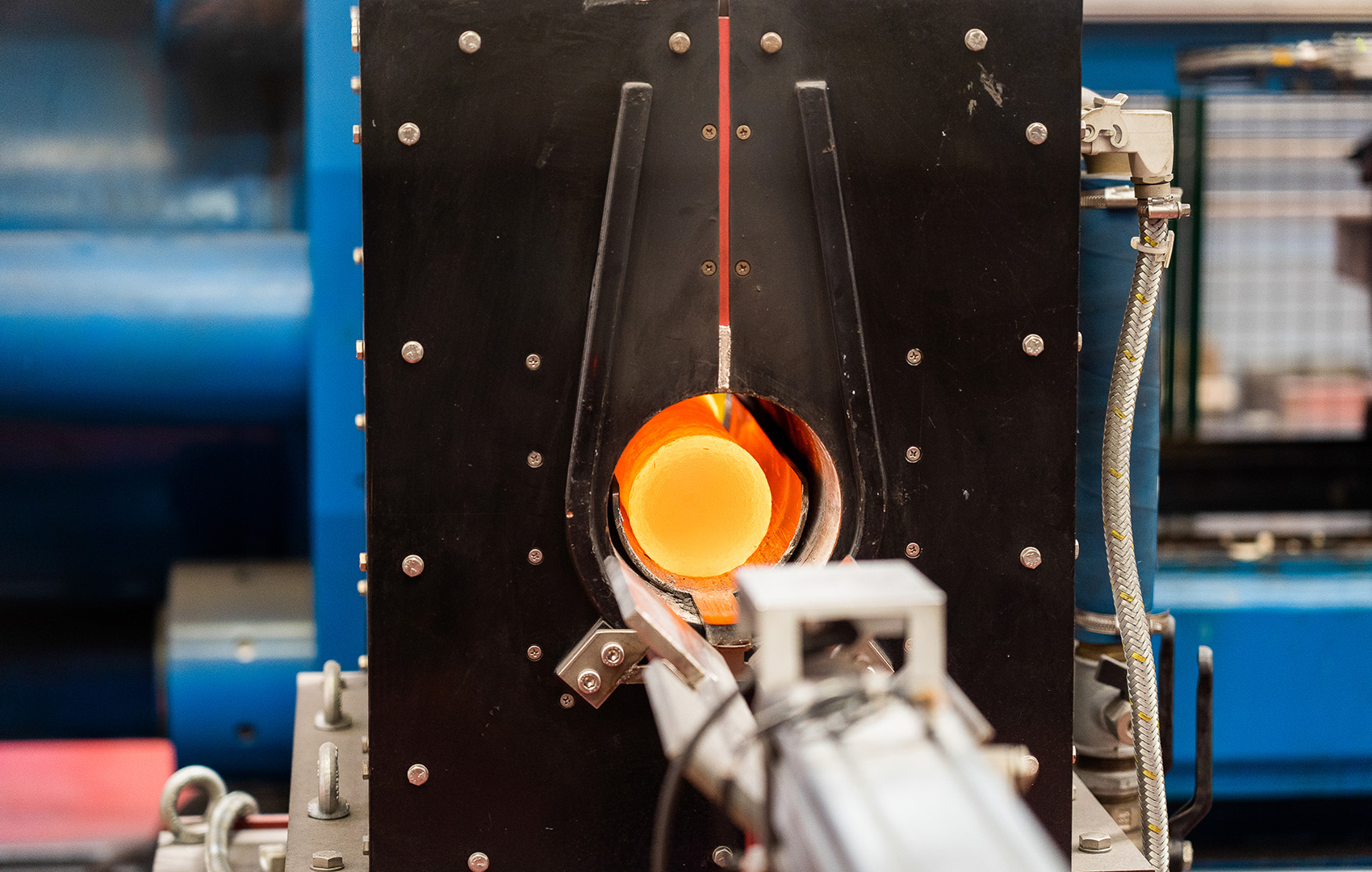

Customization is a fundamental component in our production of wires for electrical contacts. It is made possible by the specific manufacturing process. The powders are mixed to create the pseudo alloy of your choice. Then, sintering, extrusion and drawing follow.

Why you should rely on us for the production of wires for electrical contacts

We are the perfect production partner for you because we put your needs at the center.

We find the solution that adapts to your every need thanks to state-of-the-art laboratories and the use of innovative technologies. We aim to offer you a timely and high quality service, we aim to reduce waste!

We find the solution that adapts to your every need thanks to state-of-the-art laboratories and the use of innovative technologies. We aim to offer you a timely and high quality service, we aim to reduce waste!

Wires for electrical contacts: our materials

You can request wires for electrical contacts in:

Choose your alloy, we'll take care of the rest!

- AgNi 90/10

- AgNi 85/15

- AgNi 80/20

- AgNi 70/30

- Other compositions on request (ex: Ag999, AgCu, etc ...)

Choose your alloy, we'll take care of the rest!

What is your advantage?

With our wires for electrical contacts we can guarantee you a tolerance on the finished diameter of 0.01 mm, drawing thin diameters of less than 1 mm. Your every need finds a solution here, in Syntesalloys! You will no longer have to search far and wide for someone who knows how to perfectly meet your needs for these products. In Syntesalloys you have found a partner for the production of your wires for electrical contacts.

Main

characteristics

- Product dimensions: Diameter range: from 0.8 mm to 3 mm, with tolerances up to 0.01 mm.

- Chemical-physical characteristics: Tensile strength and/or hardness according to request. Excellent electrical and thermal conductivity, even for long periods of work.

- Packaging: Precision winding.

- Certification: We certify each batch.

- Surface: Skin-passed wire, for a high quality and brilliant surface finish.

- Good weldability and workability.

- Order quantity: From 5 kg.